The following types of stresses are induced in the rim of a flywheel. While massive the rotors ran at a surface speed of 20 ms 2 which is low by modern standards.

Pdf Design And Analysis Of Flywheel For Different Geometries And Materials

At present the research and application of permanent magnet and electromagnetic bearings in many countries are mature and the latest research is high-speed flywheel products based on superconducting magnetic levitation.

. 1first the amount of energy required for the desired degree of smoothening must be found and the mass moment of inertia needed to absorb that energy determined. Tensile bending stress caused by the restraint of the arms and 3. The speed of the flywheel is 10 times the speed of the crankshaft.

Procedure Calculation of torque due to pressure force Calculation of pressure force P P S cos α P Use the Indicator diagram The pressure force at given T Sh cos α crank angle can be obtained T Ph S using the indicator diagram α lnr The. R2 Flywheel outer radius. Cast iron 7250 kgm 3.

Tensile stress due to centrifugal force 2. The material of flywheel on most applications will be either cast iron or cast steel. A flywheel energy storage system or flywheel battery is a mechanical battery that stores energy kinetically in the form of a rotating mass and uses the inertia of the spinning mass to store or generate power.

2then flywheel geometry must be defined that caters the required moment of inertia in a reasonably sized package and is. Design a rimmed flywheel if mean radius of rim is 05 m and ρ of CI used for flywheel is 7150 kgm 3. This New design of flywheel saves weight by 65252kg compared to existing designs.

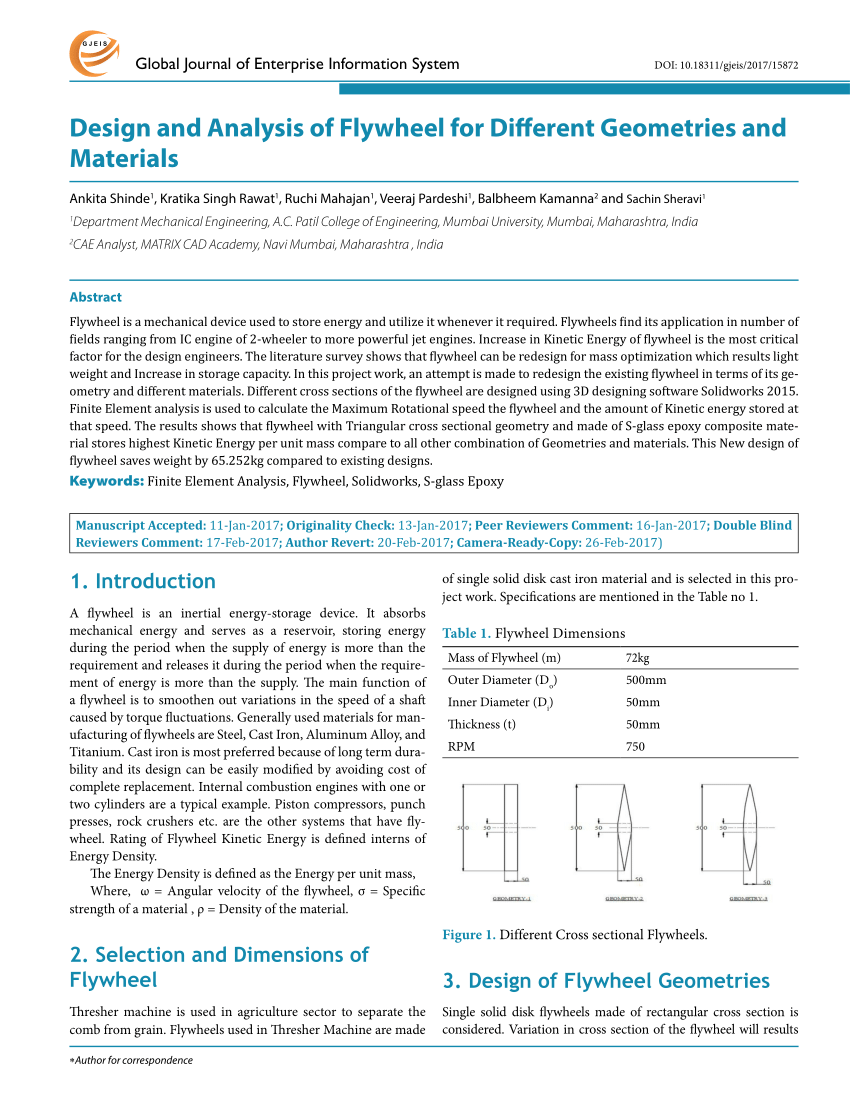

There are two stages to the design of a flywheel. The efficiency of the mechanical drive is 95. Different Cross sectional Flywheel Models.

The power of a flywheel is determined by the maximum amount of energy that it can store per unit load. In its situation the clutch wont completely release. The punching operation takes place in 16 th of the cycle.

The flywheel design problem is then formulated as a numerical optimization problem with the coefficients of the thickness function as its design variables and the minimum and maximum thicknesses of the flywheel as its constraints. I 2IπR bϼ 2 ii 2mπR bϼ Now substituting the values 1. Procedure Design of a Flywheel.

Calculation of the flywheel mass. Stress distribution and KE of Geometry 1 with Cast Iron. 43 Analysis of design-C.

Design of Flywheel and Simple Solved Problems on Flywheels. Assume that 90 of moment of inertia of flywheel is. 431 Analysis and Result.

45 Flywheel Design 451 Mass Moment of Inertia of Flywheel for an IC Engine 452 Mass Moment of Inertia of Flywheel for a Punching Press 453 Design of Flywheel 46 Summary 47 Key Words 48 Answers to SAQs 41 INTRODUCTION In practice there are two following types of cases where reciprocating engine mechanism is used. This will cause a various level of gear grinding when the gear is change. Flywheel Design Critical Dimensions.

This paper considers the problem of a mechanical system design with a variable moment of inertia. Engines of that time employed flywheels as large as 30 feet in diameter weighing as much as fifty tons. Clutch draggingthis flywheel dilemma is similar to that of clutch slipping.

Common Problems of Flywheel. Arial Garamond Times New Roman Wingdings Edge Flywheel Problem Finding acceleration and velocity Finding acceleration and velocity Kinetic Energy Material consideration Stress-Strain relations Stress-Strain relations Stress-Strain relations Equation of Motion for ur Equation of Motion for ur Stress field Stress field Product bound. The design-C is analyzed at its four typical working stages respectively.

Choose a suitable value for coefficient of fluctuation of speed and calculate mass moment of inertia I of the flywheel. The suggested system consists of a rotating disc with the ability to change the angle of inclination by means of a rod and a slider mounted on the rotation axis. Noteworthy Flywheel Failures Flywheels have represented a potential hazard since the large steam engines of the industrial era.

The composite flywheel is meant for use in vehicle energy storage and braking systems. Numerical Problems on Flywheel Design Turning Moment Diagrams Maximum Fluctuation of Energy Dimensions of a Flywheel Rim Dynamics of Mach. R1 Flywheel inner radius.

I 2IπR bϼ 2 π05420062 7800 2 2215kg-m2 ii 2mπR bϼ π05420062 7800 4443kg. Let Rradius of flywheel bbreadth of flywheel ϼdensity of material ωangular speed FORMULA USED. Decide the type of flywheel to be used the material of the flywheel and the allowable tensile stress for the.

Tentatively four sectional blocks are cut from the flywheel and the design-C is made as in Fig. Flywheels also made of high-strength steel. In fact it might lead to complete failure of putting the car into first gear when starting from a standstill.

Following are the faults that occur when a flywheel is defective. Up to 5 cash back Determine the maximum fluctuation of energy from torque versus angular displacement diagram for a given problem. Rod 10gmm 2142006 ACRME2092006 2142006 ACRME2092006 4 Design of a Flywheel.

Cast steel 7800 kgm 3. The shrinkage stresses due to unequal rate of cooling of casting. These stresses may be very high but there is no easy method of determining.

Kinetic energy is the energy of motion as quantified by the amount of work an object can do as a result of its motion expressed. Now J f and m f are 113962 kgm 2 and 135130 kg respectively. DESIGN OF FLYWHEEL Design Equation- IS 𝑬 𝒌 𝑪 𝒇 𝝎 𝒂𝒗𝒈 𝟐 where Cfis the co-efficient of speed fluctuation and Ekis the kinetic energy and 𝝎avg is the average rotational motion.

The Density of the materials d is as follows. Design problem is formulated for punching machine which has to be make holes of 30 holesminute in a steel plate of 18mm. Design equations and techniques are described making possible the dynamic.

The ultimate shear strength of the steel plate is 450 MPa.

Dynamic Modelling And Control Design Of Advanced Energy Storage For Power System Applications Energy Storage Free Energy Free Energy Projects

Flywheel Concept By Jim Collins Flywheel Collins Good To Great

Flywheel Design And Sizing Calculation Example

Modeling Optimization And Detailed Design Of A Hydraulic Flywheel Accumulator Hydraulic Accumulator Optimization Hydraulic Energy Storage

What Is A Flywheel This Is A Metal Disk With A Diameter Of 300 To 400 Mm On Its Periphery There Are Teeth Mechanical Engineering Design Flywheel Car Mechanic

Dynamometer By Dtec Homemade Dynamometer Constructed From Steel Tubing Aluminum Plate A Flywheel Brake Software Development Metal Working Tools Homemade

14 Flywheel And Governors Basic Mechanical Engineering 2nd Edition Mechanical Engineering Mechanical Energy Learning Objectives

0 comments

Post a Comment